Packaging box structures

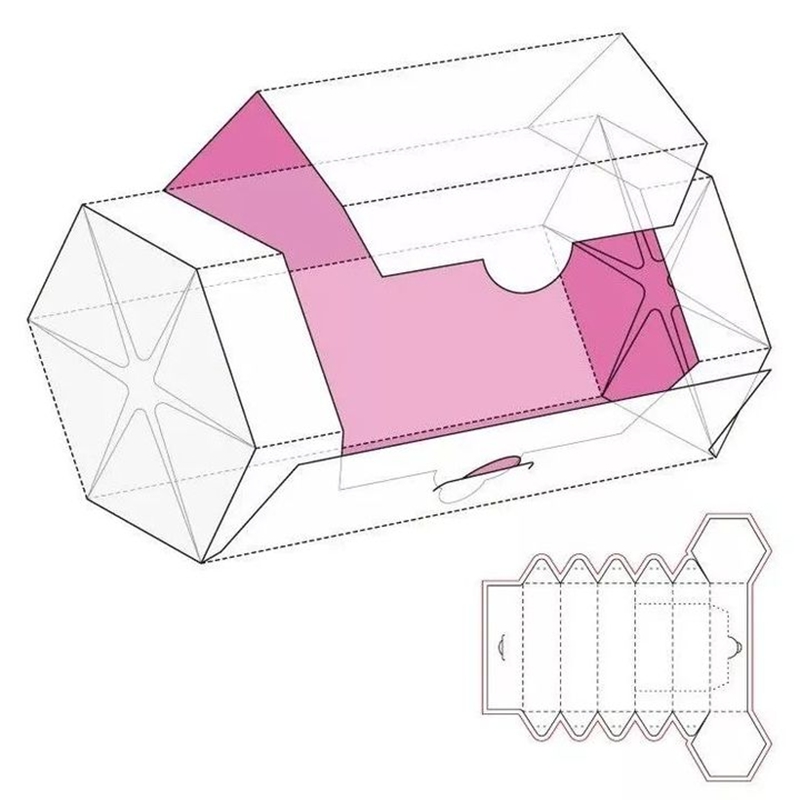

Tubular packaging structure design

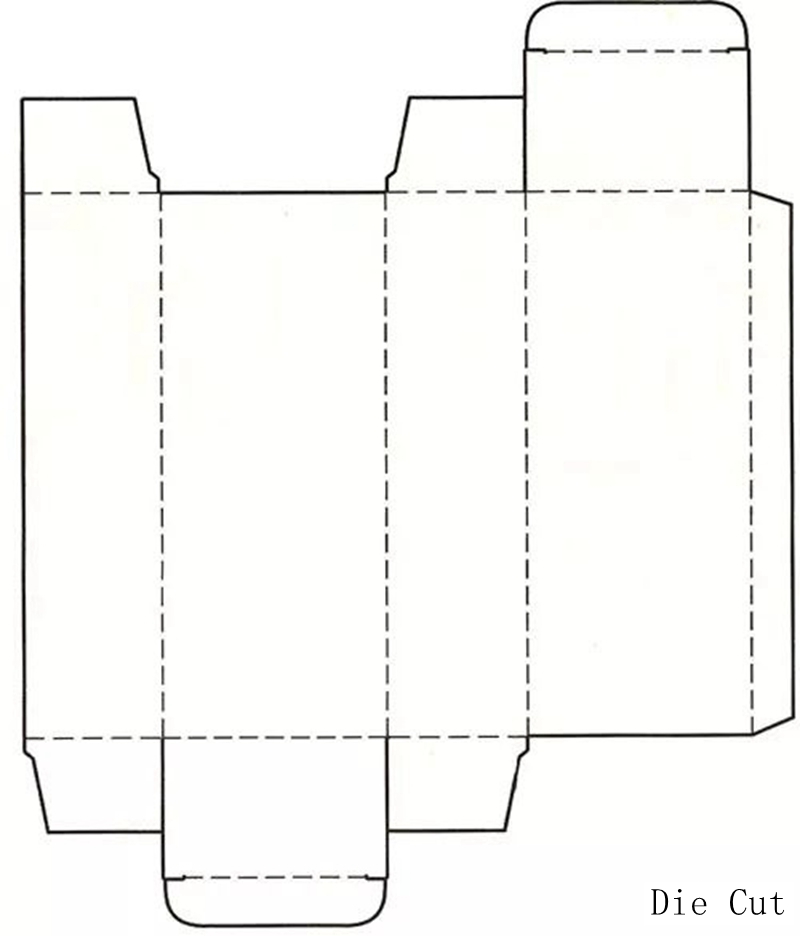

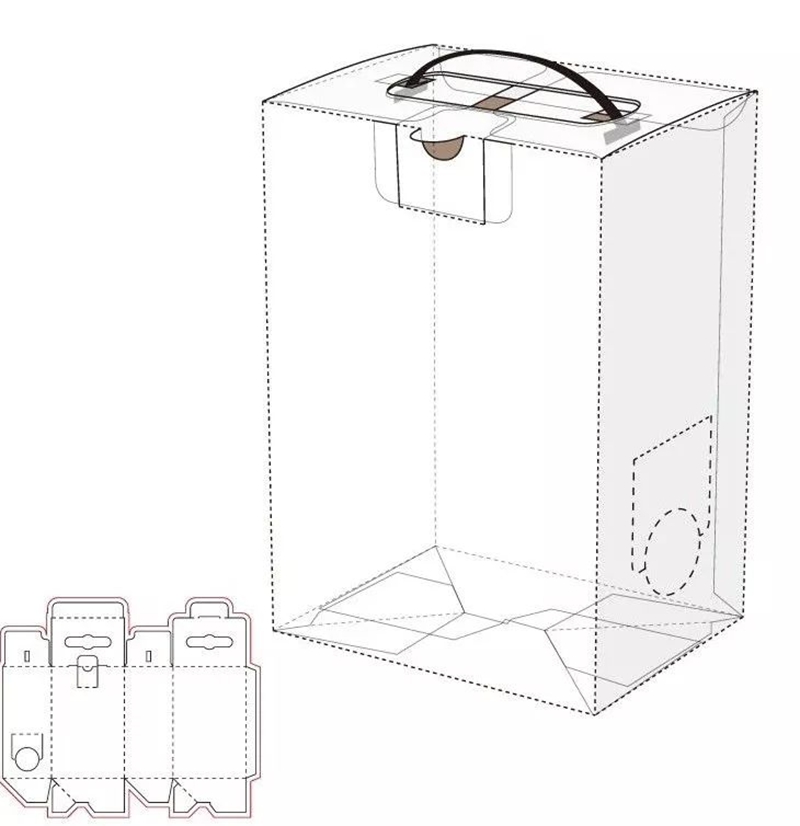

Tube-type packaging boxes are the most common form of daily packaging. Most color box packaging such as food, medicine, daily necessities, etc. adopt this packaging structure. Its characteristic is that in the molding process, both the lid and the bottom of the box need to be folded and assembled (or glued) to fix or seal, and most of them are of a single structure (the unfolded structure is a whole), and there are adhesive openings on the side of the box body , The basic shape of the carton is a quadrilateral, and it can also be expanded into a polygon on this basis. The difference in the structural features of the tube packaging box is mainly reflected in the assembly method of the lid and the bottom. Let's look at the different lid and bottom structures of the tube packaging box.

Lid structure of tube type packaging box

Therefore, the structural layout calls for basic assembly as well as convenient opening, which not only protects the goods yet likewise fulfills the opening requirements of specific packaging, such as numerous openings or single anti-counterfeiting the way to open up. The structure of the cover of the tube packaging box mainly has the following approaches.

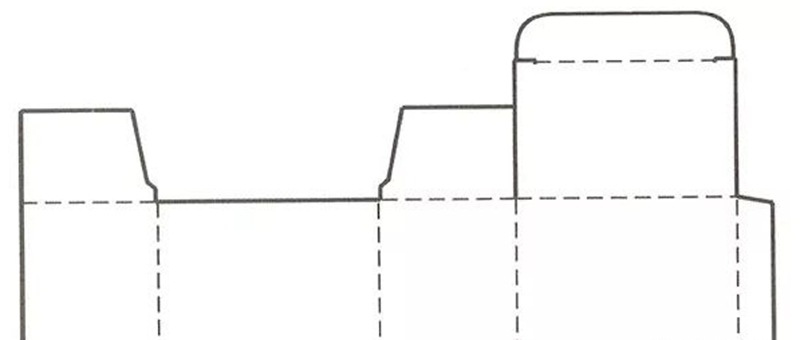

Insert flap type

The box cover has 3 flap parts, and the main cover has an elongated tongue for placing right into package body for sealing. Attention should be paid to the occlusal relationship of the flap when designing. This kind of cover is the most widely used in tube packaging boxes.

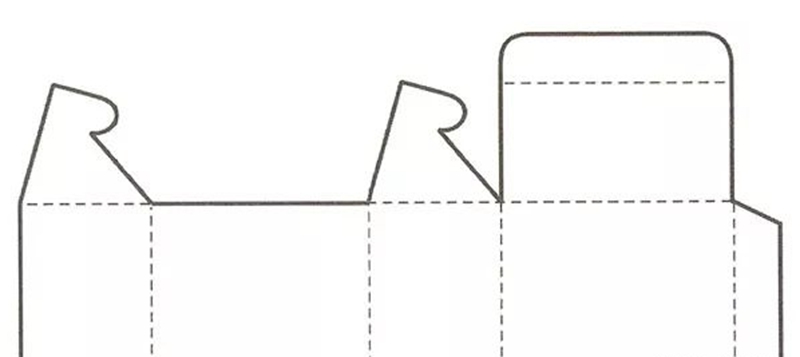

Lock

In this structure, the flaps on the front and back sides are plugged and locked to each other to make the sealing stronger, but the assembly and opening are slightly troublesome.

Mortise lock

A way of combining plug-in and lock-in, the structure is stronger than that of the plug-in flap type.

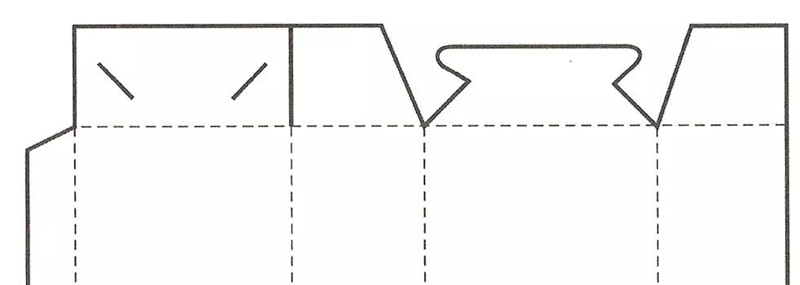

Double plug-in type

This structure enables the swing cover to be double-occluded, which is very firm, and the bite of the swing cover and the tongue can be omitted, which is more convenient for repeated opening and use.

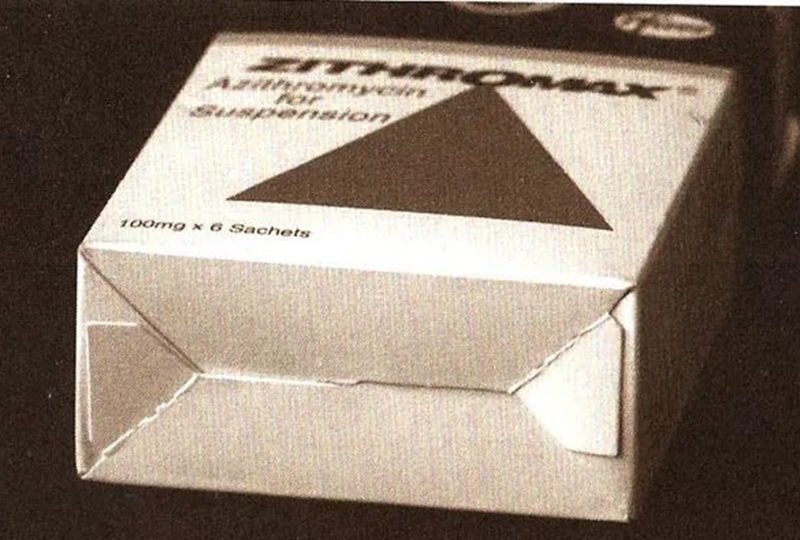

Adhesive sealing type

This bonding method has good airtightness and is suitable for automated machine production, but it cannot be opened repeatedly. It is mainly suitable for packaging powdery and granular products, such as washing powder, cereals, etc. Once opened, it cannot be reused.

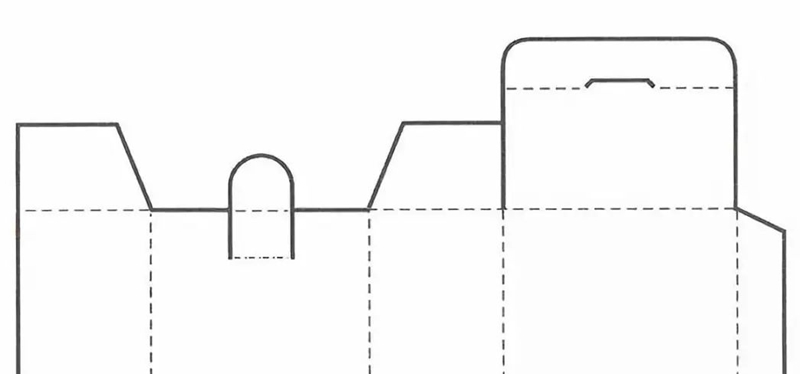

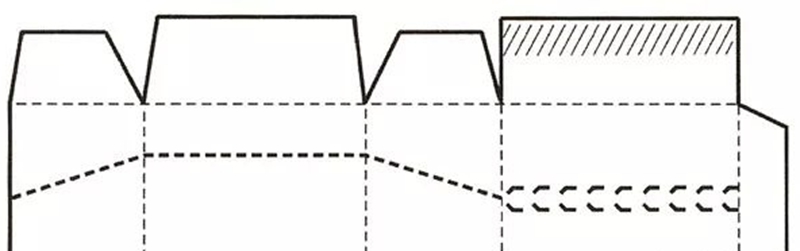

One-time anti-counterfeiting

This type of packaging structure is characterized by the use of tooth-shaped cutting lines to destroy the packaging structure while the consumer opens the packaging, preventing someone from reusing the packaging for counterfeiting activities. This kind of packaging box is mainly used for medicine packaging and some small food packaging, such as film packaging/paper towel paper packaging boxes are also currently opened in this way.

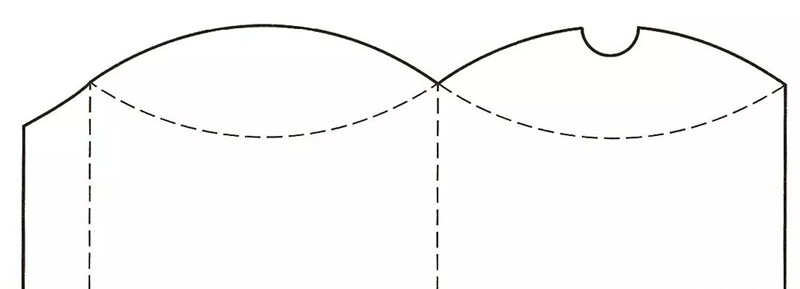

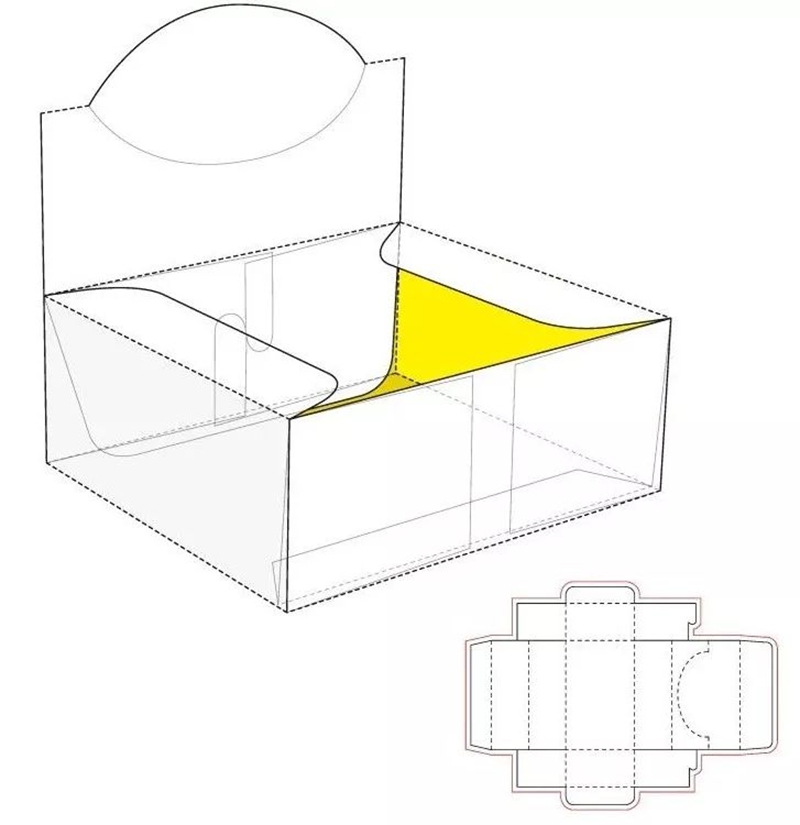

Positive press-sealing

Utilizing the paper's fold-resistance and toughness characteristics, the use of curved fold lines and pressing down the pressure wings can achieve sealing. This structure is extremely convenient to assemble, open, and use, and is the most paper-saving, and the shape is also beautiful, which is suitable for packaging small commodities.

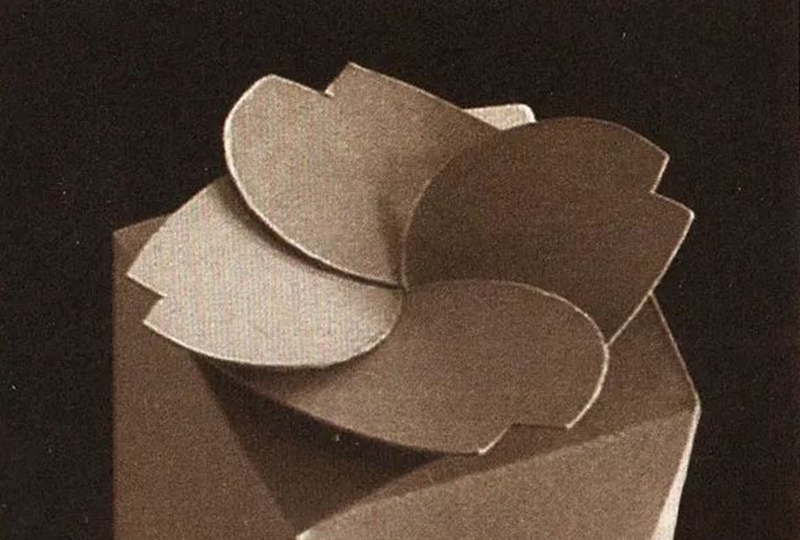

Continuous swing wing nest

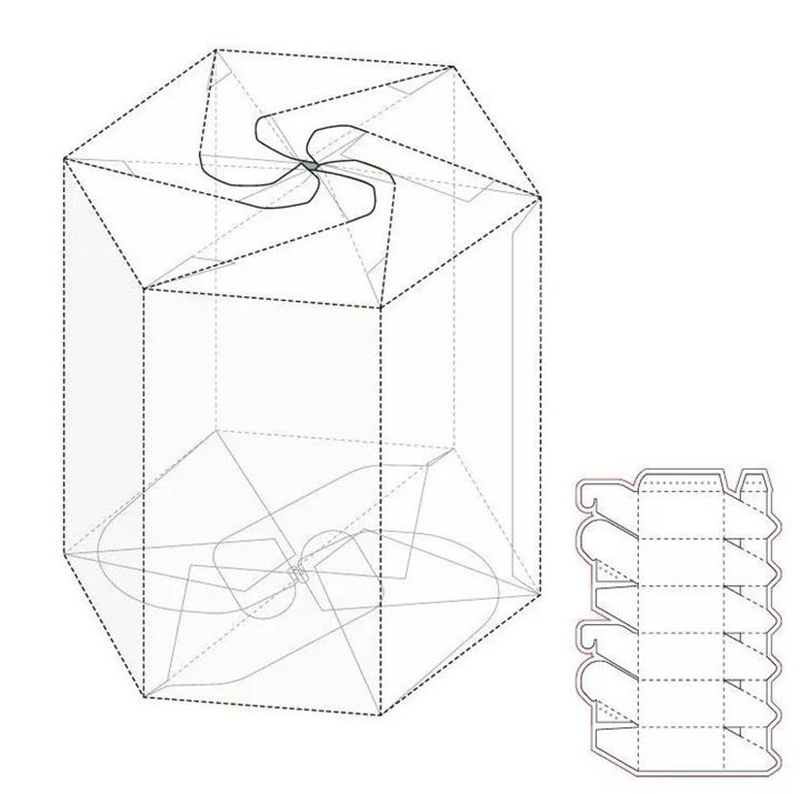

This kind of locking packaging structure is beautiful in shape and very decorative, but it is more troublesome to assemble and open by hand. It is suitable for gift packaging and is used in wedding candy packaging boxes and Christmas gift packaging boxes.

The bottom structure of the tube packaging box

The bottom of the box bears the weight of the product, so firmness is emphasized. In addition, when filling goods, whether it is machine filling or manual filling, simple structure and convenient assembly are basic requirements. There are mainly the following methods for the bottom of the tube packaging box.

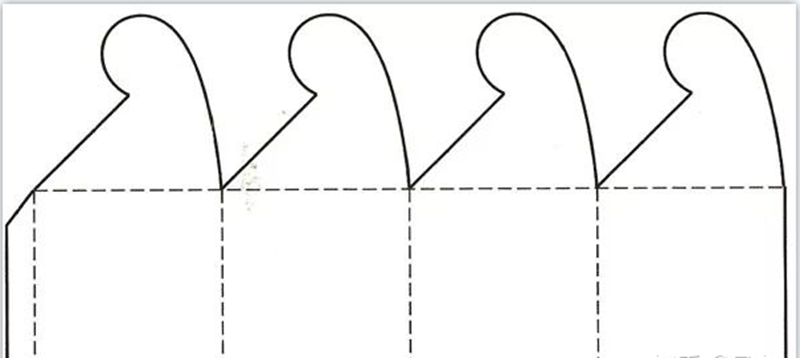

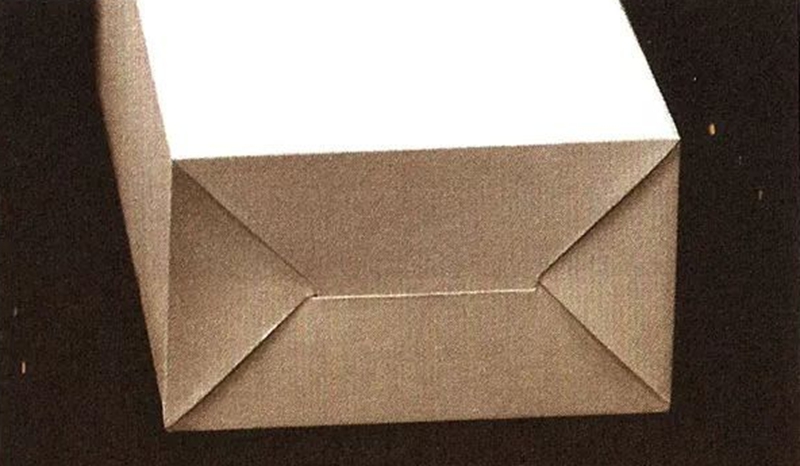

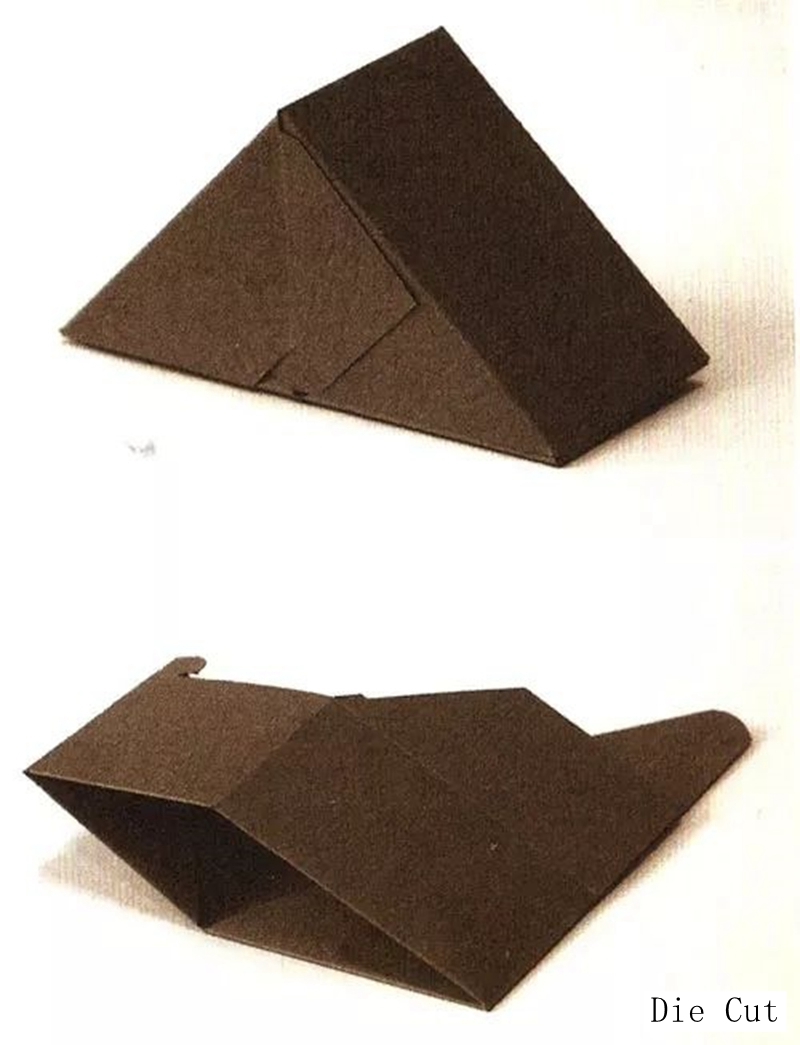

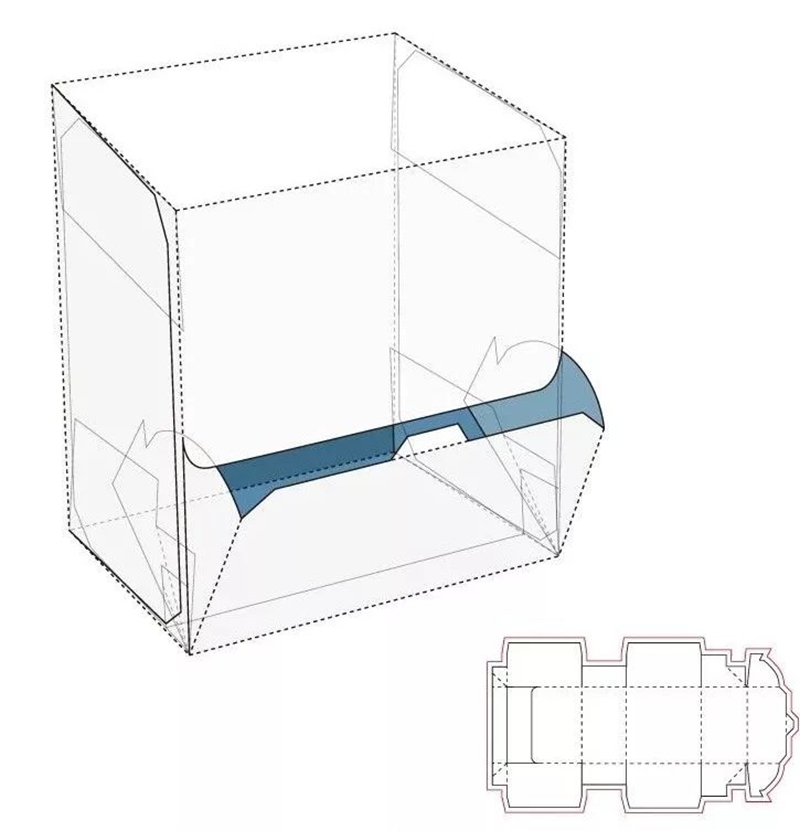

Self-locking bottom

Utilizing the 4 rocking wing parts at the bottom of the tube packaging box, they are designed to have an occlusal relationship. This kind of occlusion is completed by two steps of "doing" and "inserting". It is easy to assemble and has a certain load-bearing capacity. It is widely used in tube packaging boxes.

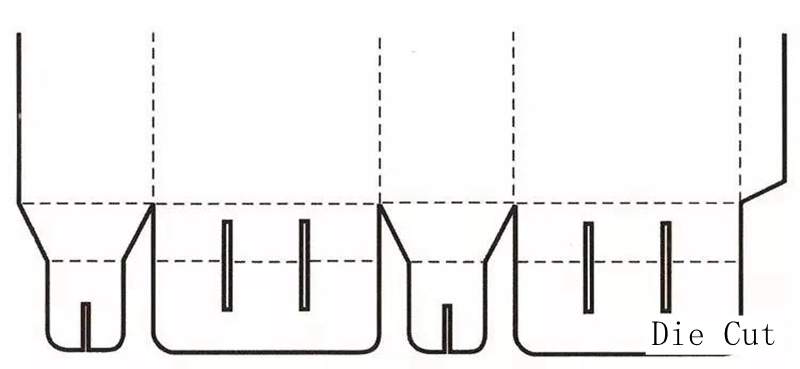

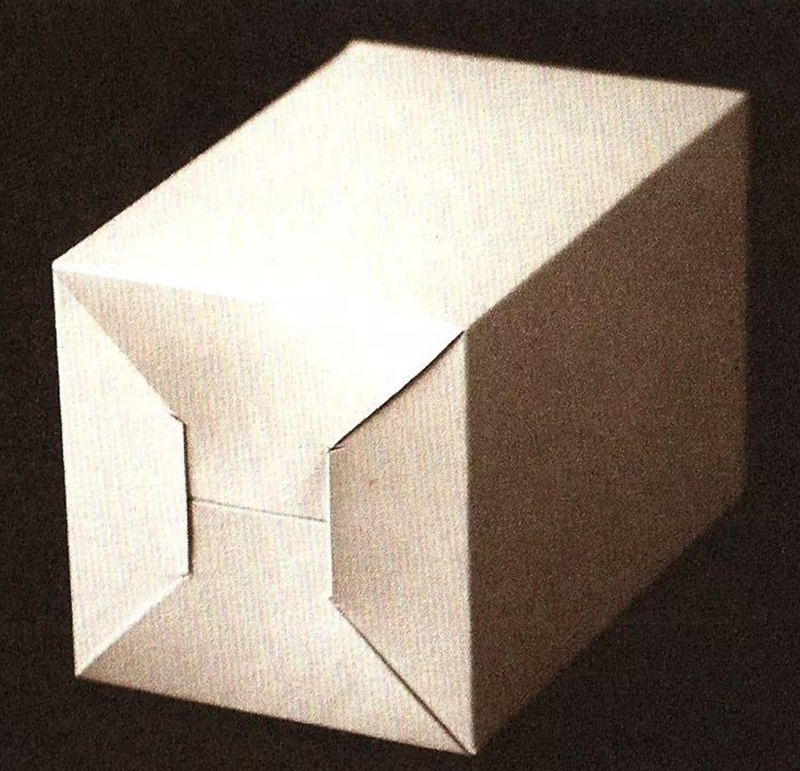

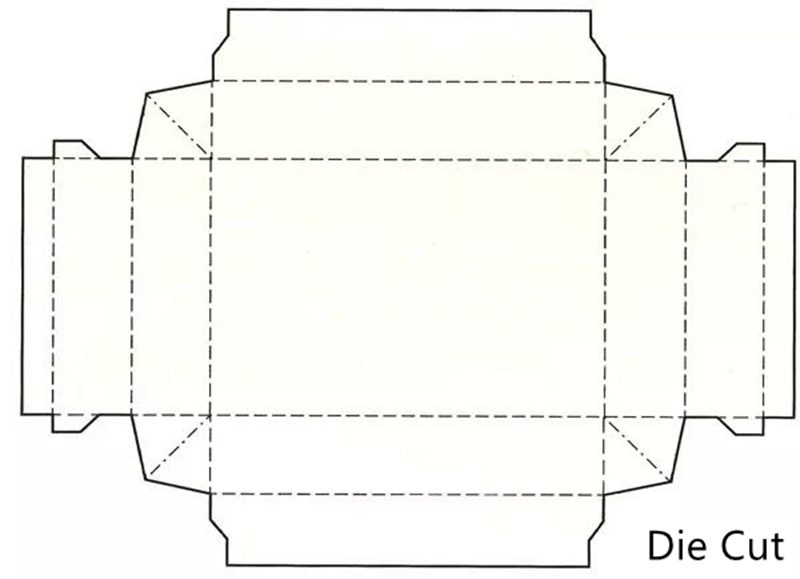

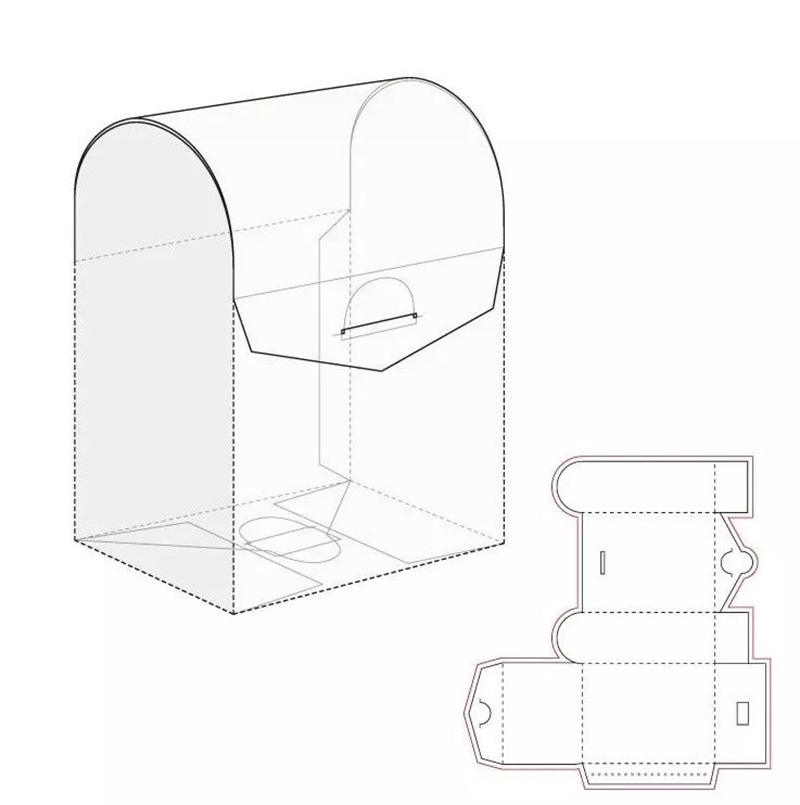

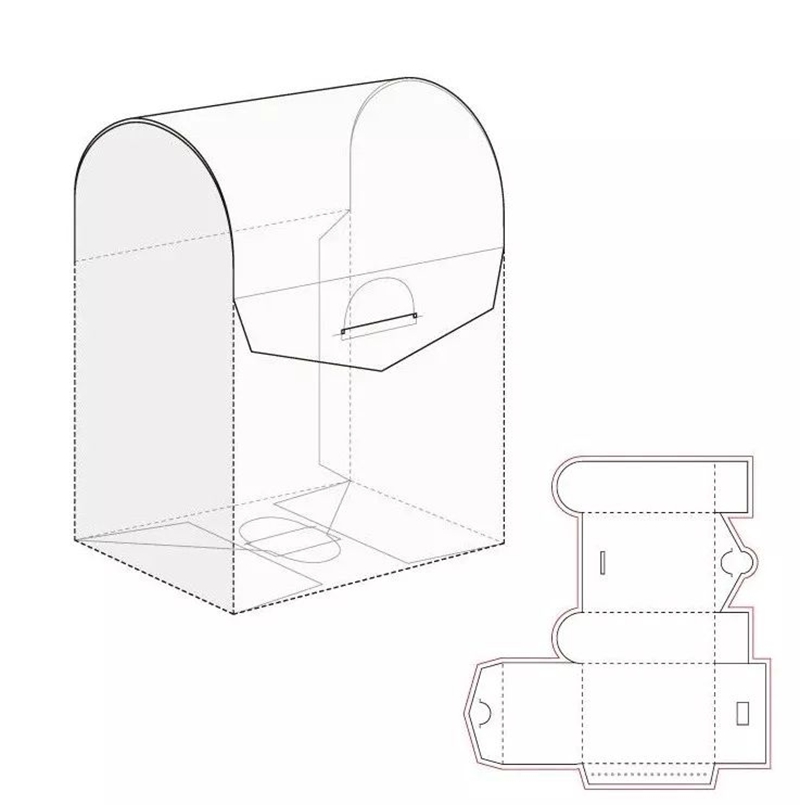

Automatic bottom lock

The automatic bottom locking packaging box adopts a pre-adhesive processing method, but it can still be flattened after bonding. As long as the box body is opened during use, the bottom of the box will automatically return to the locked state, which is extremely convenient to use, time-saving and labor-saving, and It has good load-bearing capacity and is suitable for automated production. This design structure is generally used for packaging designs that carry high-weight items.

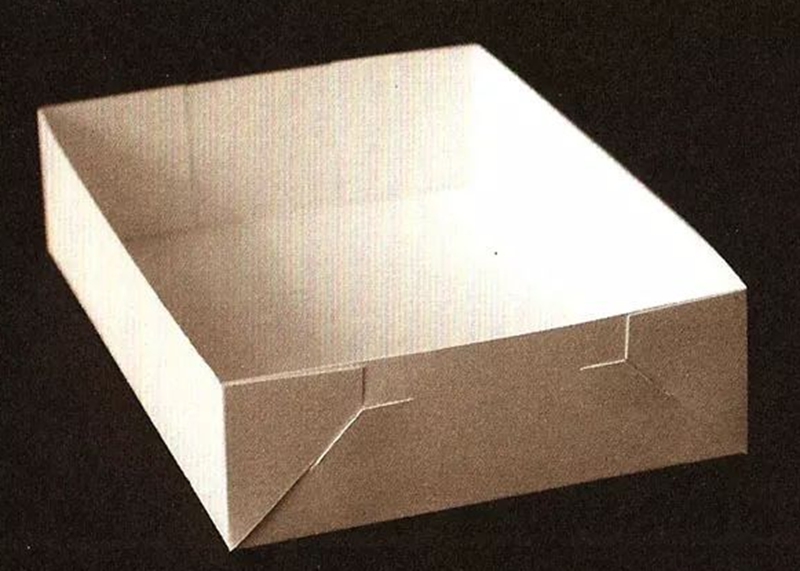

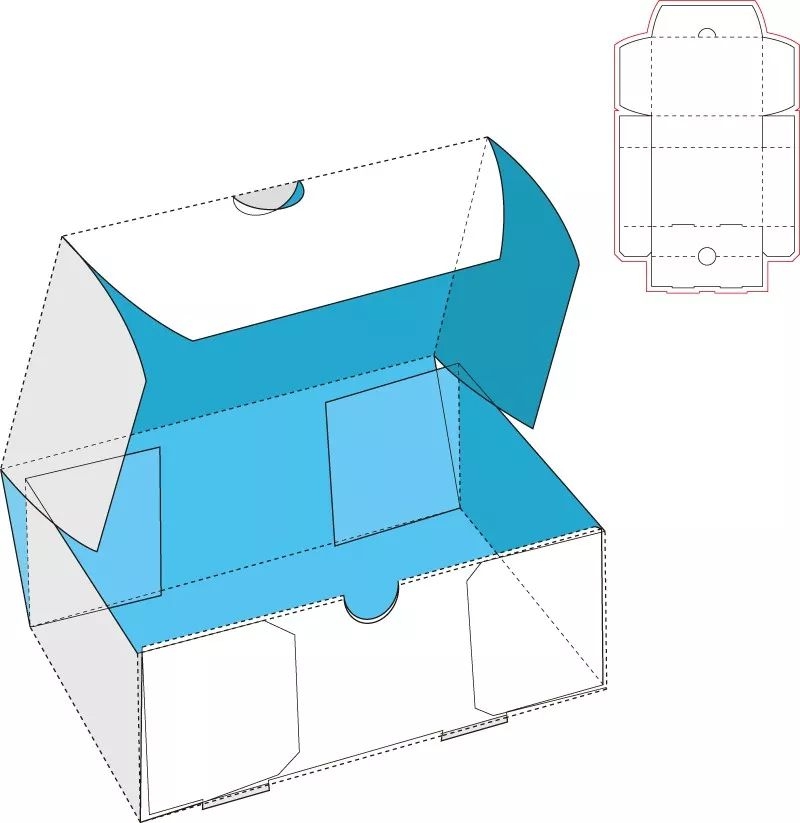

Swing lid double socket type back cover

The structure is exactly the same as the swing-lid plug-in box lid. This design structure is easy to use, but the load-bearing capacity is weak. It is usually suitable for packaging small or light goods such as food, stationery, toothpaste, etc. It is the most common packaging box design structure.

Bottom-closed partition

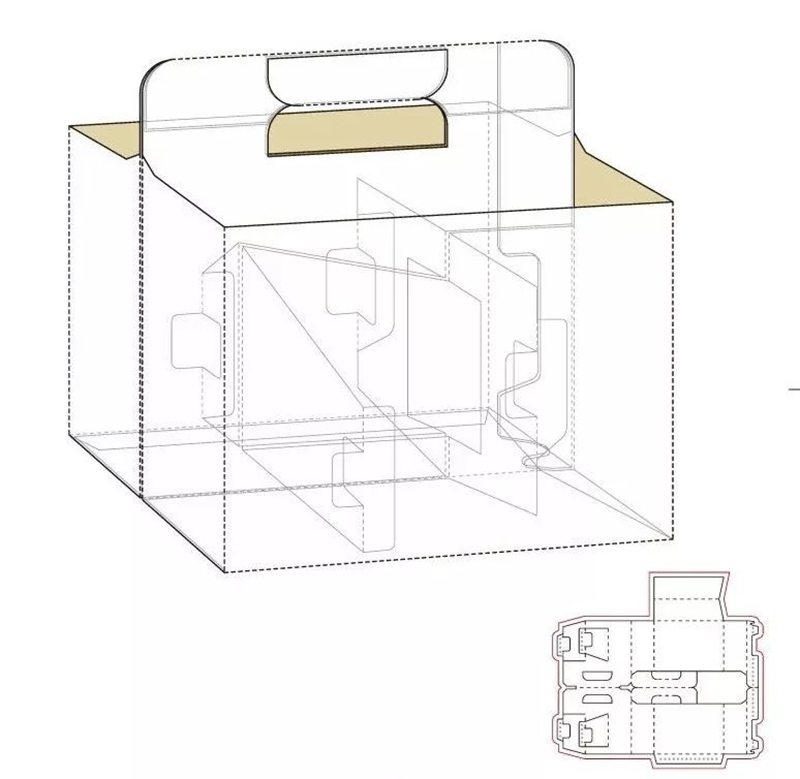

The bottom-closing structure of the partition wall is a structure with the function of partition walls in the four rocking wings of the tube-type packaging box. After assembly, partitions will be formed inside the box body to effectively separate and fix the goods and play a good protective role. The partition wall is integrated with the box body, which can effectively save costs, and the structure of the packaging box has high compressive strength.

Other evolutionary structures

According to the above commonly used basic packaging box structure models, other structural forms can also be evolved through design.

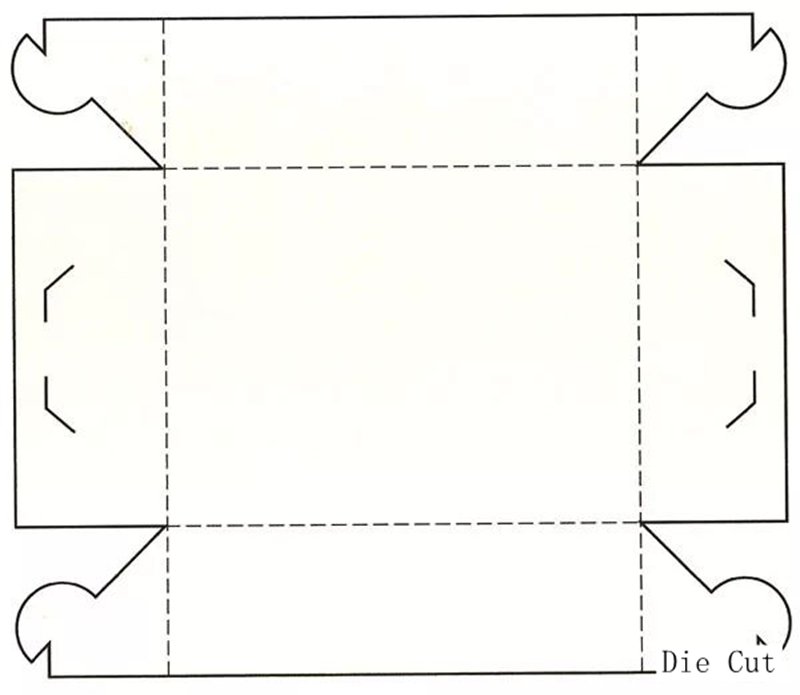

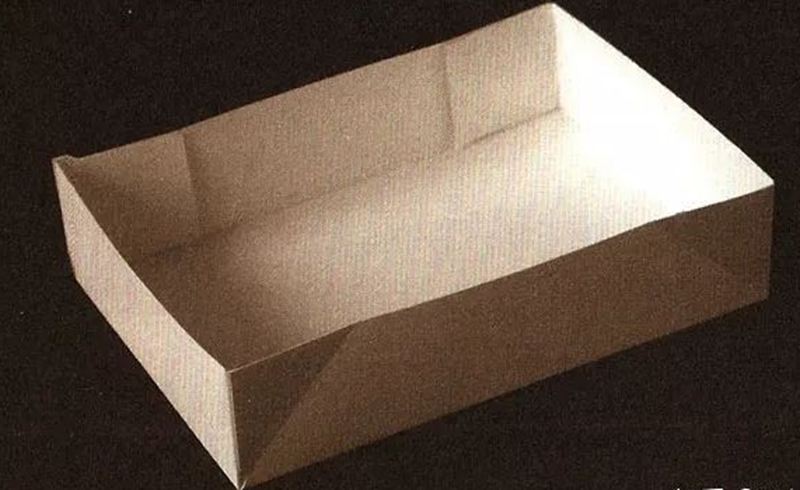

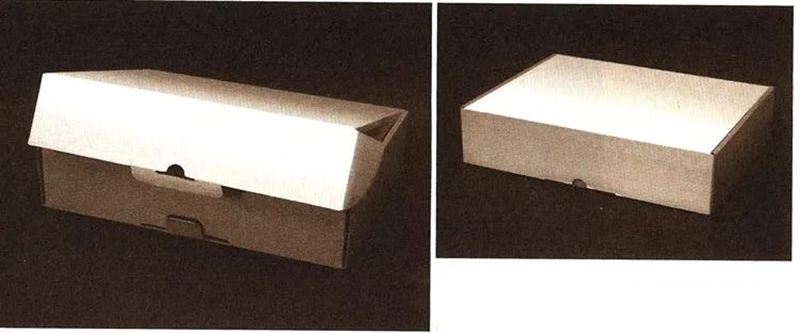

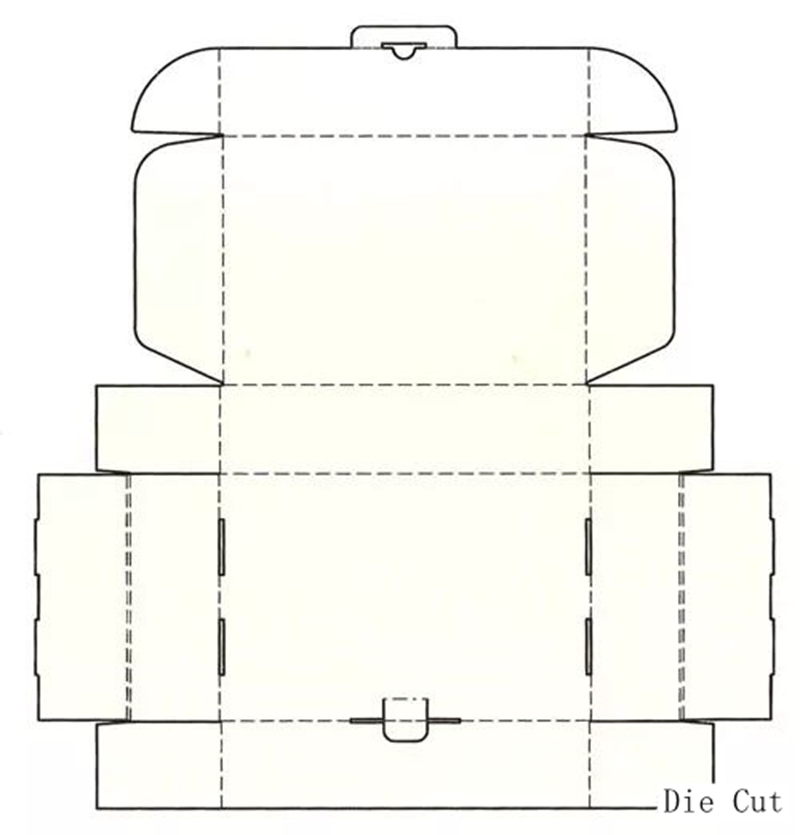

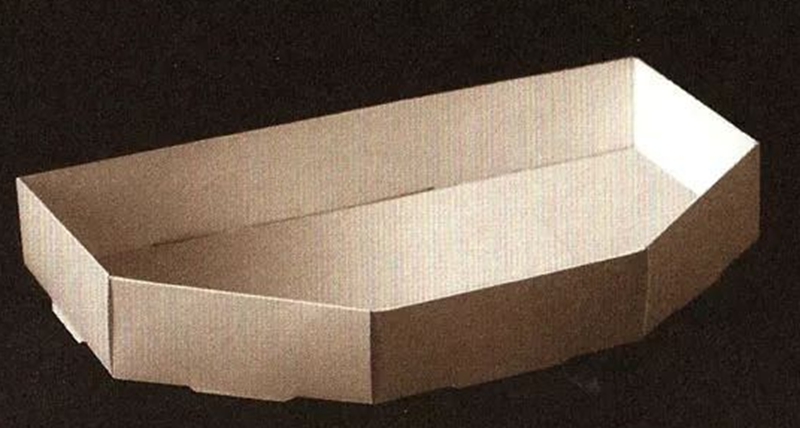

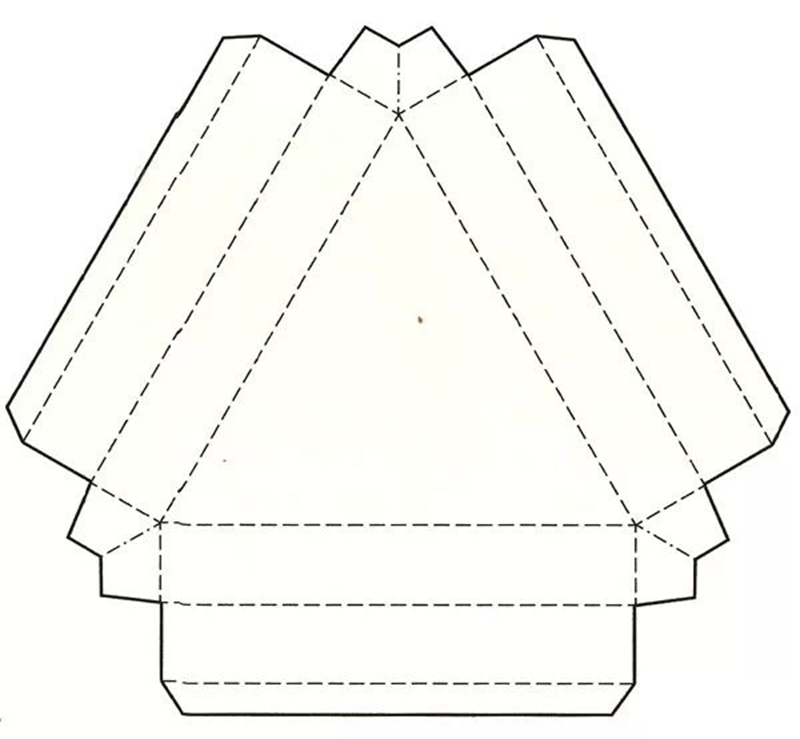

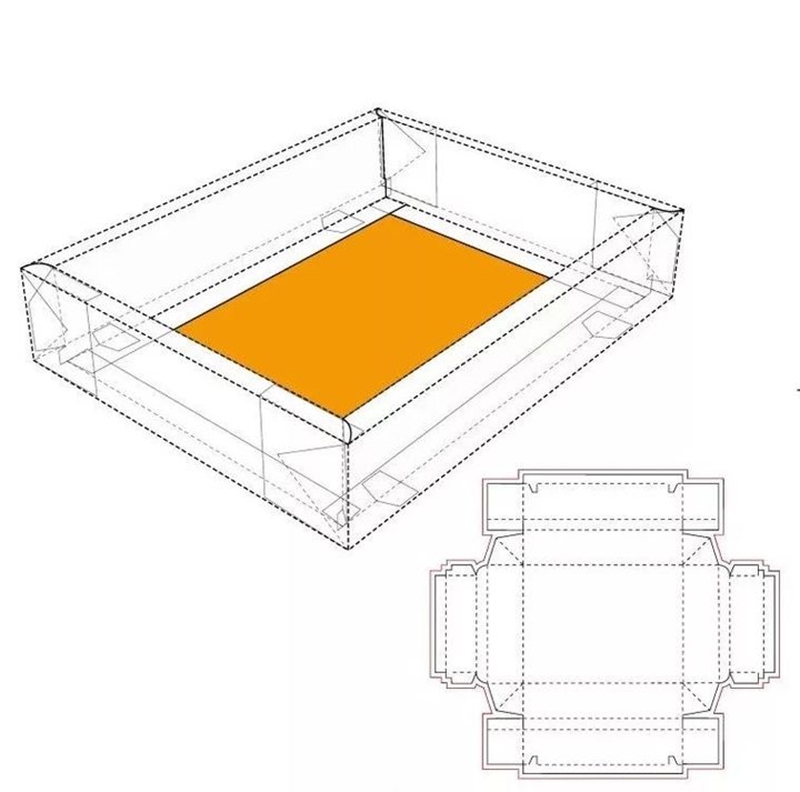

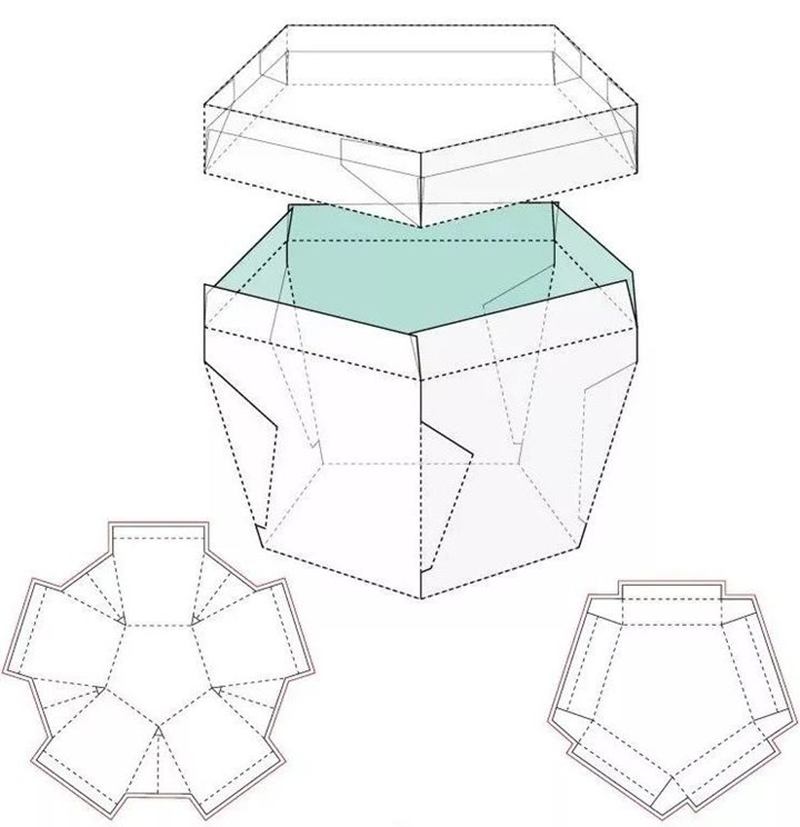

The structure of the disc packaging box is a carton structure formed by folding, snapping, inserting or gluing the edges of the cardboard. This type of packaging box usually has no changes on the bottom of the box, and the main structural changes are reflected in the box body. Tray packaging boxes generally have a small height and a large display surface after opening. This kind of carton packaging structure is mostly used for packaging textiles, clothing, shoes and hats, food, gifts, handicrafts and other commodities, among which the structure of heaven and earth cover and airplane box The most common form.

The main forming method of disc packaging box

1) No-inserting and assemble: there is no bonding and locking, easy to use.

2) Locking assembly: The structure is made stronger by locking.

3) Pre-adhesive assembly: Partial pre-adhesion makes assembly easier.

Lock assembly

Rre-adhesive assembly

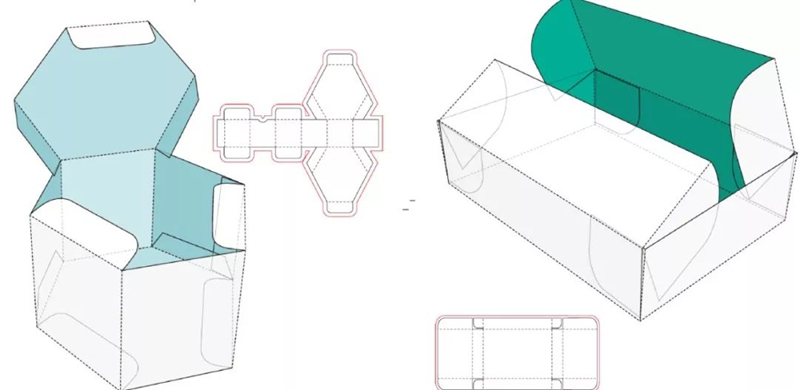

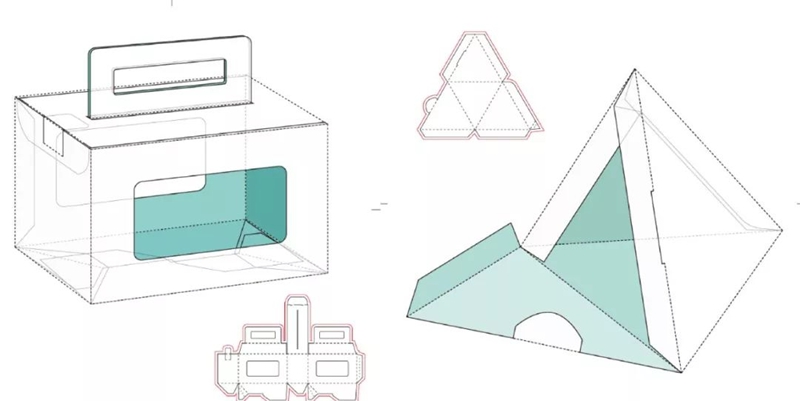

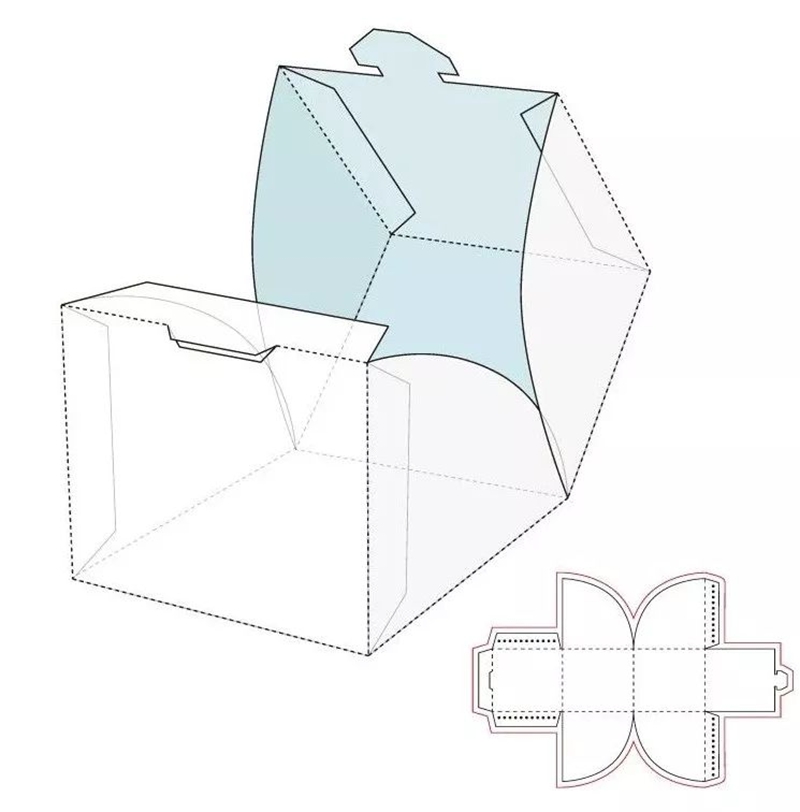

The main structure of the 2-tray packaging box

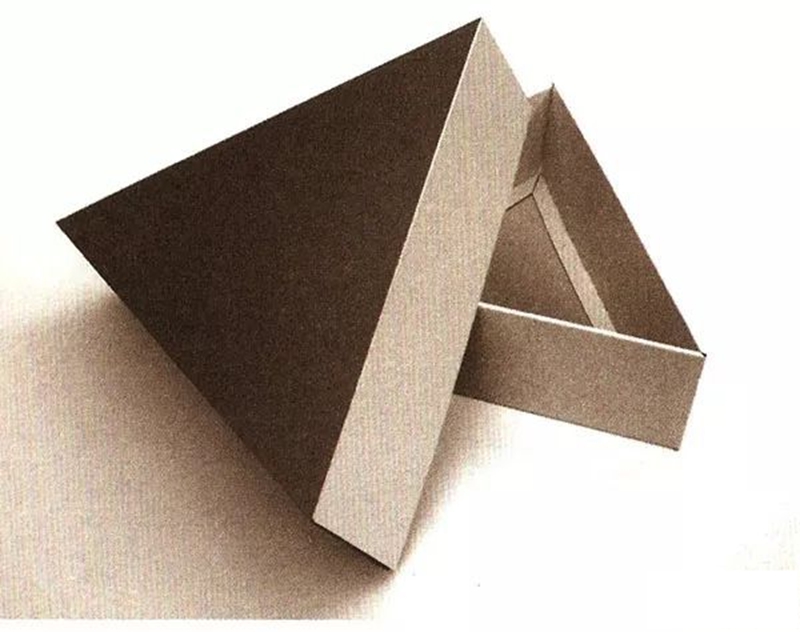

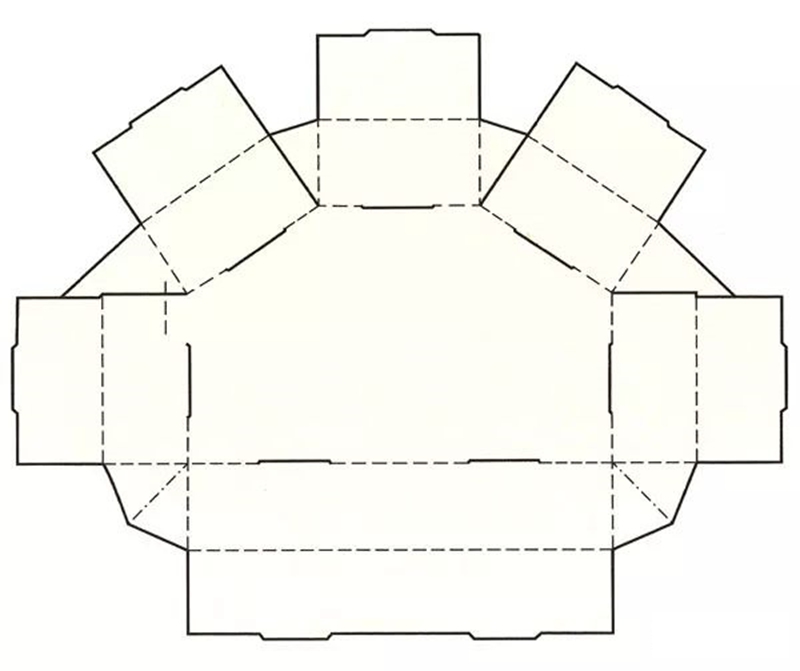

1) Cover type: The box body is composed of two independent disc-shaped structures covering each other, which is commonly used in the packaging of clothing, shoes and hats.

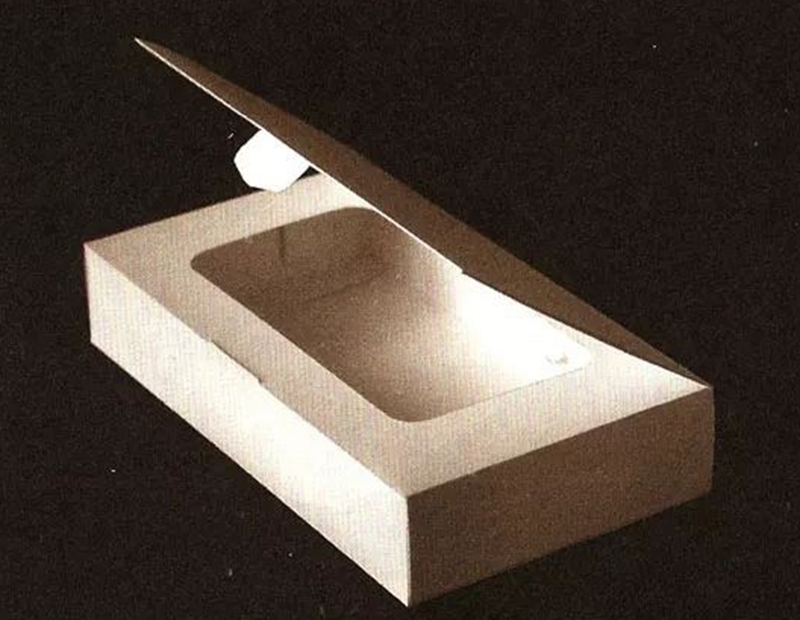

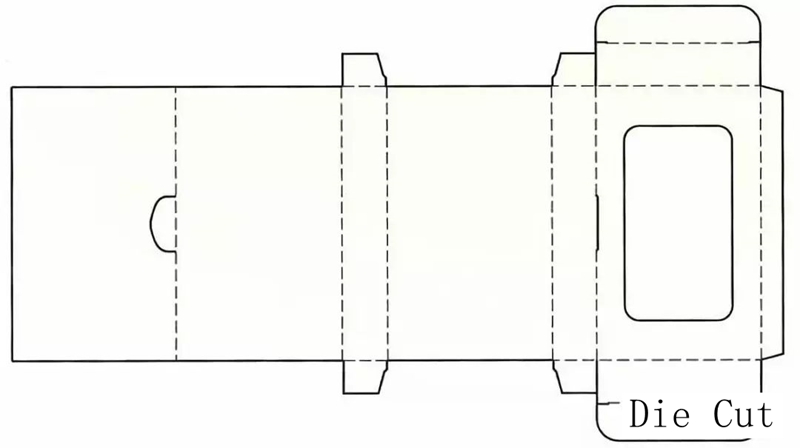

2) Rocking lid type: On the basis of the disc packaging box, one side is extended to design a rocking lid, and its structural features are more similar to the rocking lid of a tube packaging box.

3) Continuous inserting type: Its inserting method is more similar to the continuous rocking wing nesting type of the tube-type packaging box.

4) Drawer type: consists of two independent parts, a disc box body and a jacket.

5) Book type: The opening method is similar to that of a hardcover book. The flap is usually not inserted and snapped, but is fixed by an accessory.

Swing cover

Book style

Book structure expansion diagram

Other forms

We can see that many business has increasing efforts on the product packaging. Competition is fierce and the brand effect of packaging continues to expand.

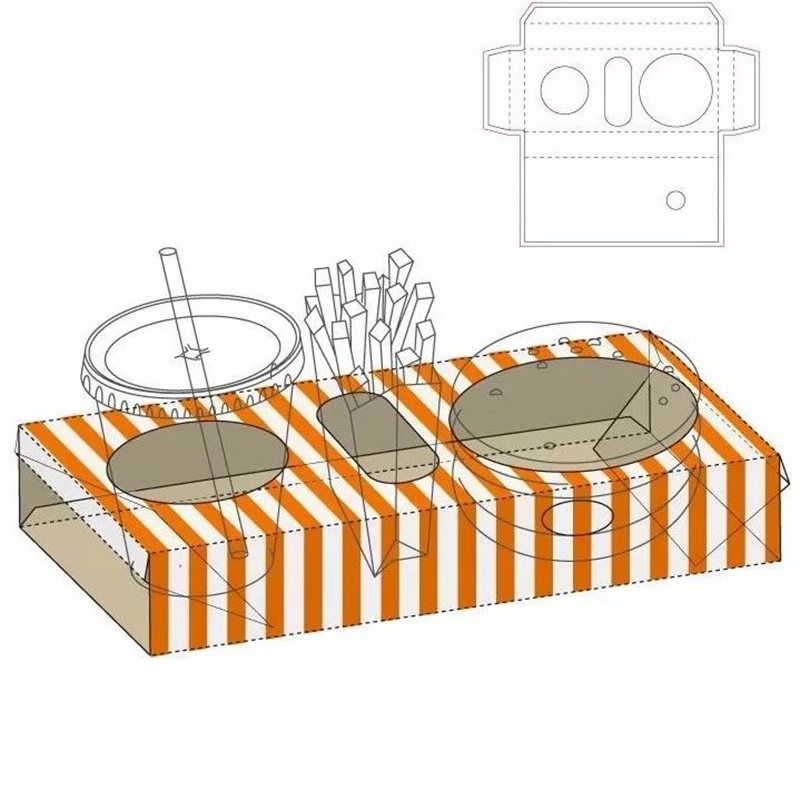

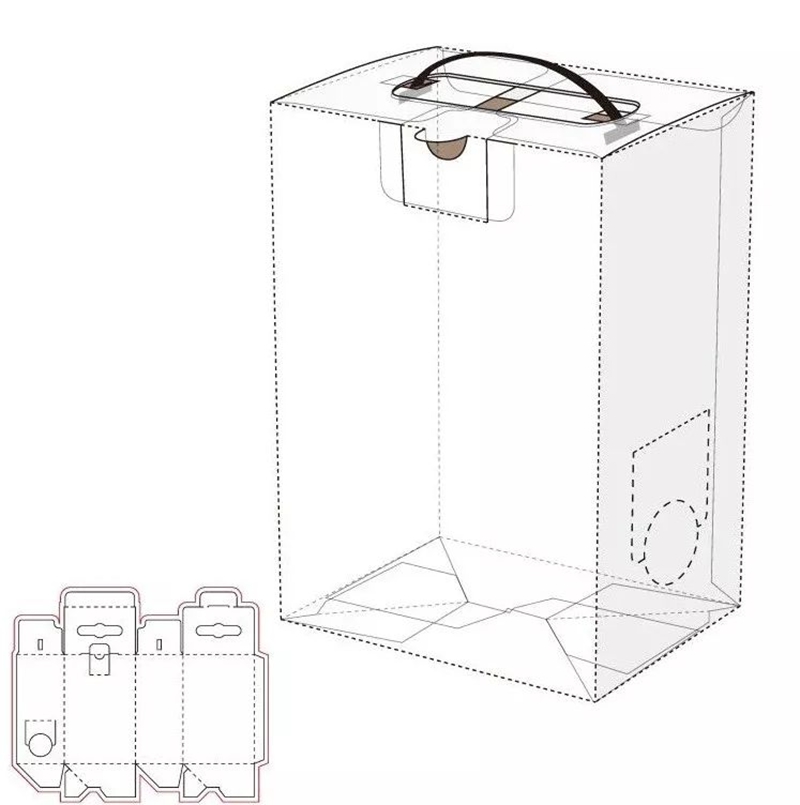

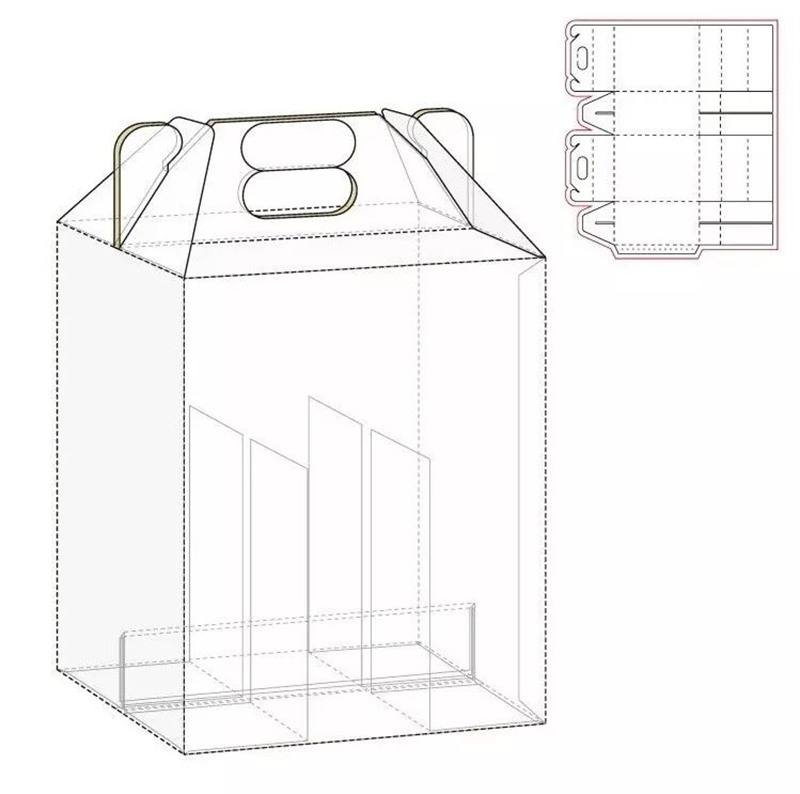

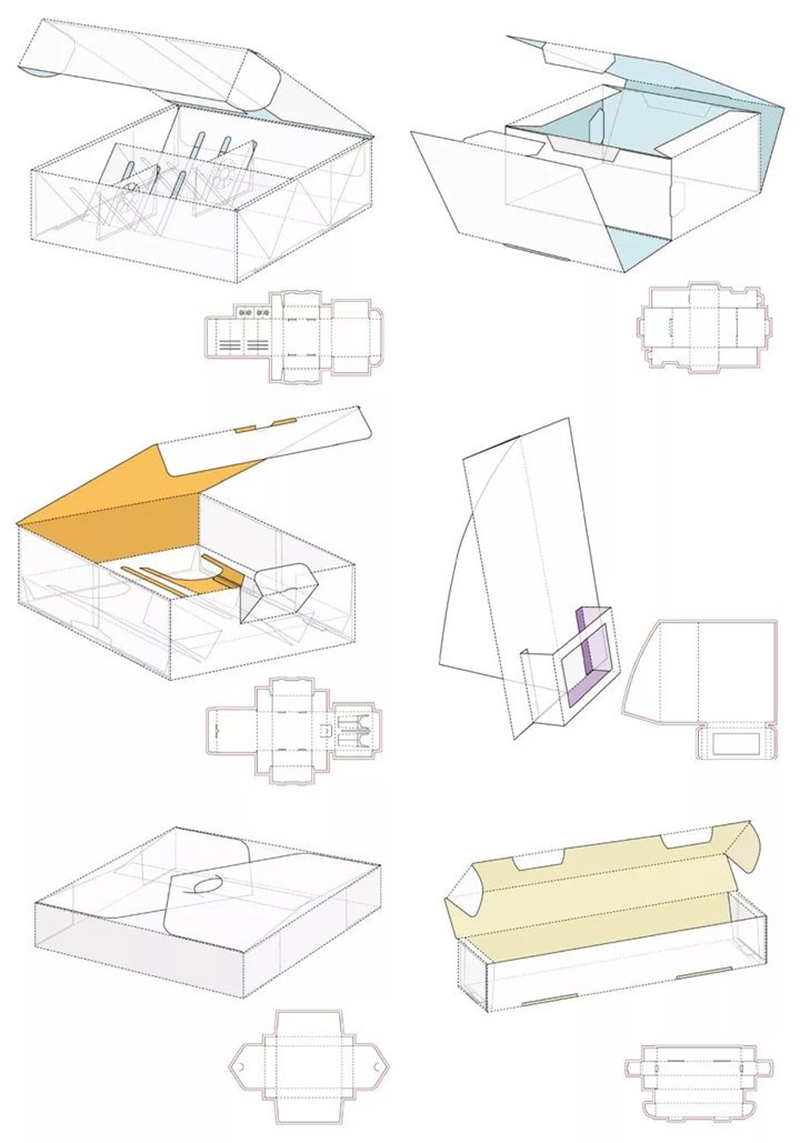

Following are more designs of box design display

If you need to customize a gift packaging box, we are here for you.

English

English German

German French

French Arabic

Arabic Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole