In the increasingly competitive global market, LOGO is not only a corporate image, but also a symbol of corporate culture. Besides, it is also a form of visual information expression formed in people's long-term life and practice, which has a certain meaning and can make people understand the visual graphics. Therefore, many companies print their LOGO on their products. We are going to talk about 10 popular logo printing methods.

10 popular logo printing methods

Preprint

It Includes flexo preprint and gravure preprint, it is printed with the help of roll web feed. The registration accuracy of this printing is very high, and the number of screen lines can be Reach 150 lines/inch. Generally, this printing method is used when the amount is large, because it has a particularly high efficiency, high overprint accuracy and will not affect the strength of the corrugated board. But it is only suitable for long run-length (long run-length), which requires a lot of quantitative requirements. After the roll sheet is printed, it is rewinded and put on the corrugated production line. The required cardboard is made by a single tile machine or a double tile machine, and then die-cut, indented, slotted, punched, nailed or glued.

Flat/offset/offset (lithography, offset)

First print a single sheet of paper. Unlike pre-printing, pre-printing is a web feed printing face sheet, and it is a single sheet feed printing. Do not go to the corrugated production line after printing, directly go to the veneer and single-sided or double-sided corrugated laminating paper, just after the subsequent processing. This kind of carton for sales packaging is very common. Offset printing can clearly restore the color, contrast and level of the original designs with high precision, and is currently the most common paper printing method. Suitable for posters, briefs, manuals, newspapers, packaging, books, magazines, calendars and other related color printed matter.

Post print

This is the printing method that everyone often sees in some small factories, which is to print the cardboard that has been mounted and pressed over the height of the line directly on the machine. The cost is low, flexible, and effective. There is no requirement for quantitative, but because flexographic printing is a kind of direct printing, the blanket cylinder will directly contact the cardboard, and the ink will be transferred to the cardboard by the pressure of the pressure roller. In this way, it is undoubtedly a kind of damage to the strength of the formed corrugated box. If the pressure is too small, a washboard will be produced, which is too large and collapses. However, this method is generally used for printing if the cartons are only used as transport packaging.

Flexography

A type of letterpress printing technology.Use rubber and soft resin as printing plate, and print with water-soluble or alcohol-soluble ink. It is very suitable for printing plastic bags, labels and corrugated paper. The fineness of printing dots and lines is gradually approaching offset printing. Flexographic printing is mainly divided into unit type flexographic printing and satellite type flexographic printing. Now satellite flexographic printing is widely used. The main advantage of satellite flexographic printing is that it can precisely control the tension of the substrate.

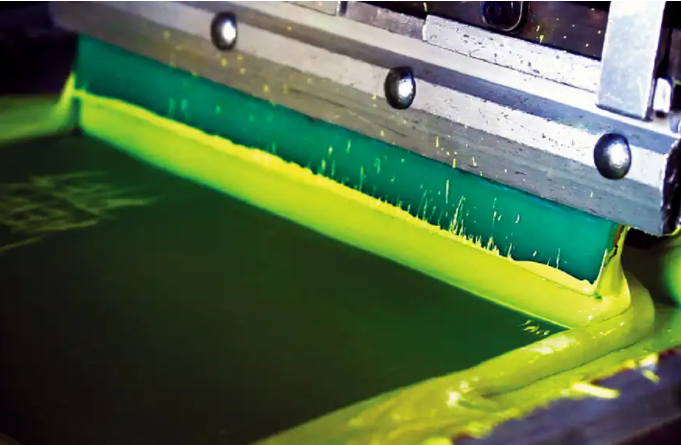

Screen Printing

As a kind of wide range of applications, screen printing can be divided into: textile printing, plastic printing, metal printing, ceramic printing, glass printing, electronic product printing, lottery silk screen printing, electronic decoration billboards according to the differences of printing materials. Silk screen printing, metal bulletin board screen printing, stainless steel product screen printing, light reflector screen printing, screen transfer anodized aluminum, screen printing and lacquer screen printing, etc.. One of the stencil printing technologies, the printing ink is particularly thick, and it is most suitable for making special effects. It requires less quantity for printing and the need for ink color density is especially suitable. It can also be printed on three-dimensional surfaces, such as square shippingboxes, gift boxes,cylinderglass vases,tin boxescans, etc. In addition to paper, it can also be printed on cloth, plastic fabrics, splints, films, metal sheets, glass, etc. Common new products include banners, pennants, T-shirts, gift boxes, soda bottles and circuit boards. The flexibility of screen printing is unmatched by other printing methods.

It is not easy to damage the product by this method, and the cost is also low.

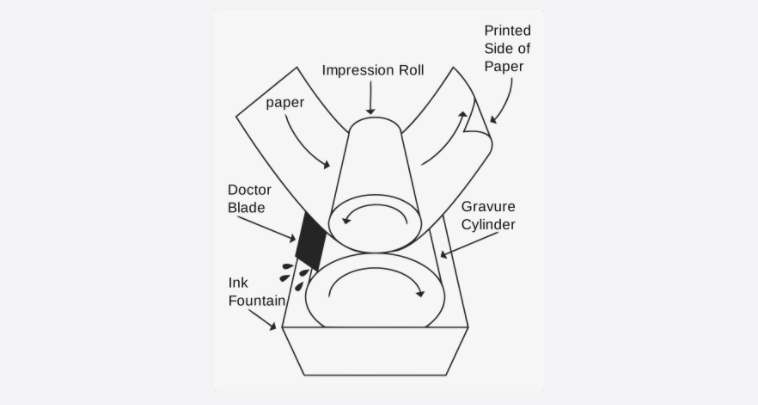

Gravure printing

It is suitable for printing high-quality and expensive prints. Whether it is color or black and white pictures, the gravure printing effect can be comparable to photographic photos. It requires quite an amount of quantity for printing since the plate-making fee is expensive so it is also one of the less commonly used methods. It is suitable for printing securities, stocks, gift certificates, commercial credit vouchers or stationery, etc.

Letterpress printing

When ink is applied to the raised surface and a piece of paper is used to cover the ink-coated surface, the ink is transferred to the paper. The method of printing using this principle is called letterpress printing. Letterpress printing is the oldest printing method. Nowadays, many different printing plates are used on different types of printing presses to print colorful and varied products, including newspapers, books and magazines.

Thermal transfer printing

- Thermal transfer printing is also called sublimation printing. In fact, it is not a new printing process. It is only recently that this process has been developed rapidly. Pad printing is to press the ink on the surface of the print head onto the product to be printed. This method is suitable for printing on polyester fiber, cotton, linen and wool, etc., and the printed LOGO has a strong three-dimensional effect, and the layers are detailed and clear.

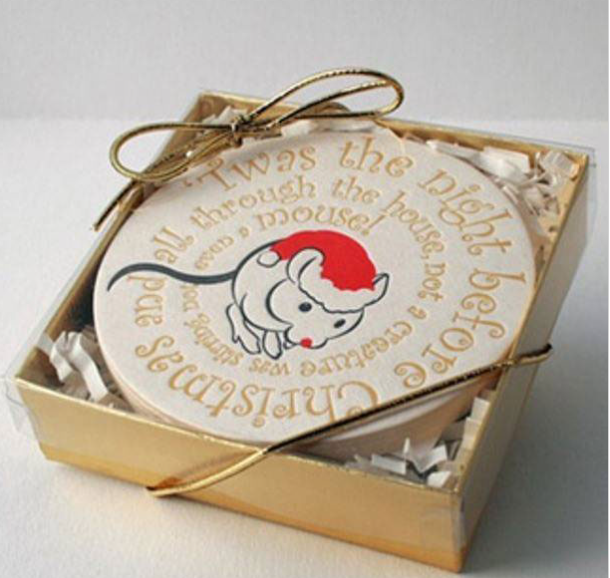

Embroidery

In fact, it is just that the traditional needle-based embroidery is changed to the modern machine-based embroidery. This method is suitable for all kinds of fabric products, and is closer to the modern technology of ancient craftsmanship, but the working method is changed from manual to machine. The LOGO embroidered in this way is very delicate, bright in color, smooth and particularly beautiful. We usually use this printing on promotional products like trucker hats, sweatbands, and stuffed animal toys, etc.

UV printing

UV printing is currently a widely used printing method. In fact, there are many printing methods on the market, but almost no printing method can completely replace UV printing. UV printing has many advantages. Not only does it have a variety of printing materials, but it can also be fast Dry, speed up printing efficiency,

What is UV printing?

UV printing is digital printing. The printing process is controlled by a computer. There is no need to open the plate like traditional screen printing, which greatly reduces the time and process of plate printing. It can also be produced in small quantities and customized. The drying method of the ink is to use (UV) ultraviolet light to cure the ink, so when the ink is printed on the material, at the same time, Ultraviolet rays make the ink dry, and the drying is completed in almost one second, so UV printing is The fastest and environmentally friendly printing currently! !

Advantages of UV printing?

Fast drying and high productivity

UV printing has the advantage of rapid drying, because special reactants are added to the ink, which will dry and solidify immediately after UV light is irradiated. After printing is almost completed, it will dry immediately, so the consumption of ink is also much less than that of traditional printing technology. In addition, UV printing is digitized by a computer, which greatly shortens the man-hours and increases the printing output, and the yield rate in the manufacturing is greatly improved!

Multiple choices of printing materials

UV printing can be used in many areas. As long as the size of the machine can be put down, it can be made by UV printing, such as glass, acrylic, PC film, PE board, foam board, PP board... etc., metal material Such as iron plate, stainless steel plate, aluminum plate, cloth and leather can also be printed with UV, so almost all materials can be made with UV printing, and because of its convenience, many materials will be changed to UV printing.

Color Effect

UV printing is characterized by bright and saturated colors. Because it has four colors of CMYK, plus white, it is particularly good in color rendering and color saturation, and UV printing can also control the color to be presented, which can be adjusted. The degree of color you want is an effect that cannot be achieved by traditional printing. UV printing can also show metallic luster. As long as the use of special inks, the bright or metallic color can be fully presented.

Waterproof, scratch-resistant and UV-resistant

Compared with traditional printing, UV printing is more scratch-resistant, abrasion-resistant, and sun-resistant. The finished product is waterproof, scratch-resistant and UV-resistant, and has a wide range of uses.

English

English German

German French

French Arabic

Arabic Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bulgarian

Bulgarian Catalan

Catalan Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Estonian

Estonian Filipino

Filipino Finnish

Finnish Galician

Galician Georgian

Georgian Greek

Greek Haitian Creole

Haitian Creole